Your individual RFID-based Kanban system for your individual C-Parts requirements.

Data is transferred immediately via the intelligent shelf on which the empty bin bearing the RFID tag is positioned.

Multiple racks can be operated by a shelf rack structure. Without any power connection at all.

Benefits: No additional space demand, maximum flexibility by different rack sizes

Using the intelligent pallet box, data for your C-Parts is transferred immediately via RFID to a separate storage position as soon as an empty bin is placed there.

Benefits: Process integrated and simple data transfer and order transfer, ideal for pallet Kanban

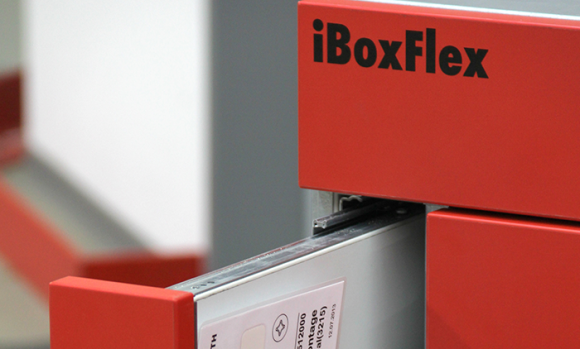

The iBOX®flex is the first pallet box on the market that can operate two Kanban systems in production simultaneously. It is suitable for both two-bin Kanban systems and pallet Kanban systems.

This is made possible by the unique design of iBOX®flex. This includes, firstly, an extending drawer for all empty bins, which means ease of handling for the foreman, logistics specialist or fitter in production. Secondly, the iBOX®flex contains a separate compartment on the side for RFID tags from the pallet Kanban.

With iPUSH®, ordering is triggered by pressing the button integrated into the RFID label on the bin.

The iGATE enables the simultaneous data transfer of a multitude of bins.

The iGATE is also the right solution for checking incoming and outgoing goods.

In the iTURN® and iROTATE® are systems, turning the bin triggers the data transfer via RFID and thus repeat ordering of the item. Only the construction of the rack distinguishes these two standard modules.

Automatic data transfer is triggered by iWEIGHT® if the weight of a bin falls below the predefined minimum level and is triggered by iSKID® if the level drops below the minimum for a pallet.